Products

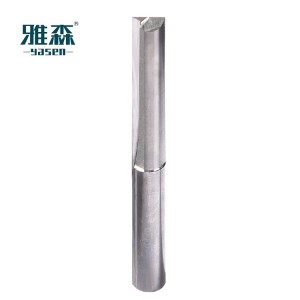

CNC woodworking Solid Carbide roughing miliing cutter

These wavy teeth, like many continuous cutting edges, produce many small chips.This results in a relatively rough surface finish, but the chips are in the form of shorter flakes and the thicker banded parts are easier to handle, resulting in smaller chips that are easier to remove.

You can tell us the shapes of teeth you want.

In the cutting process, multiple teeth are in contact with the workpiece at the same time, reducing chatter and vibration. Rapid cutting using re milling is sometimes called up milling. Rough end mills are sometimes referred to as "rippa" or "Ripper" cutters.

Because it is used in the woodworking industry, in the process of processing, we choose alloys with higher hardness, even above HRA 92.

And the processing is done in one step by a five-axis CNC grinding machine. The accuracy of the machine tool will be inspected and adjusted for each production to ensure that the final machining accuracy is within 0.01mm. Our length of rough milling cutter is always long, and most diameters of them are big. The longest one is 330mm and cutter length is 165mm. Biggest diameter is 20mm.

At the same time, for all milling cutters, our processing efficiency is very fast. The delivery date of non standardized products is within 15 days.

Rough milling cutter is often used in the keyhole processing of hardwood doors.

If you do not need a high surface finish, rough milling cutter must be your best choice.

Mianyang Yasen hardward Tools Co.,Ltd specialized in various of woodworking dowel drills, Hinge boring bits, quick joints and Solid carbide milling cutters,having excellent design, advanced production equipment, advanced detection equipment and professional team. Using a full set of advanced C N C machine production lines and advanced production technology. The material of tool bit will use the ultrafine particles of tungsten carbide, making the bit have high precision, excellent properties sharp and wearable. Controlling the product strictly and do not allow any defective products into the market. All of them are the Yasen‘s prominent characteristics. Whatever the management layer, the executive layer or the service staff all can assist the customers to solve all of the problems with the classic professionally quality and enthusiastic service.

The sophisticated equipment and the lasted technology produce good quality of product. The high quality micro grain carbide mills, forming tools, drills and reamers from Yasen have established a high reputation in Chinese Mainland, Southeast Asia, Eastern Europe and South American market.

The company follows the professional standard of operation philosophy—Profession, Innovation, Service class, and the management aim—Quality first, Customer superior. Providing the most durable professionally high-quality cutter for the development of wood industry.