Products

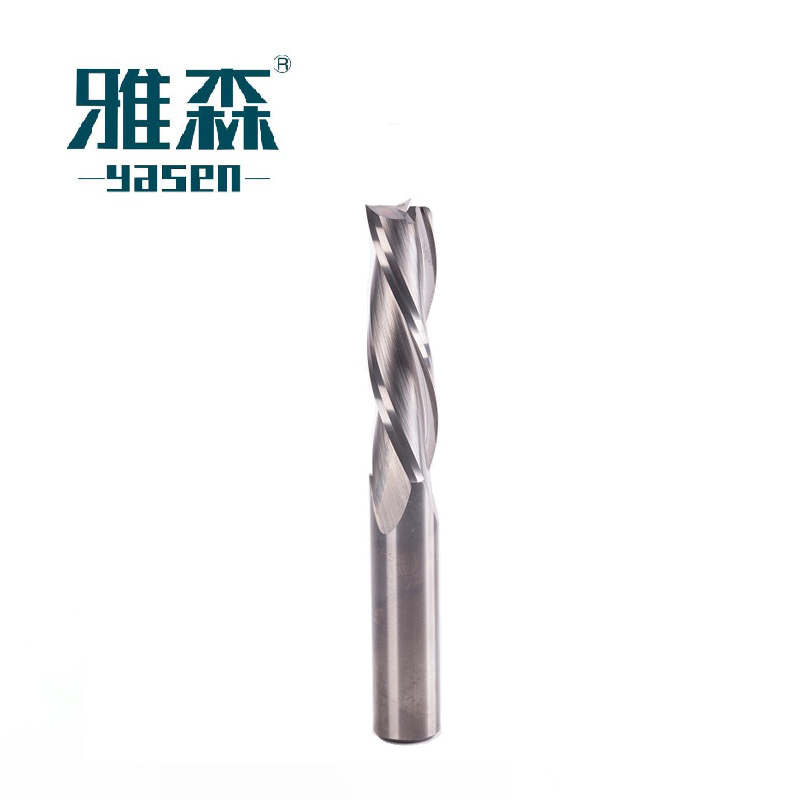

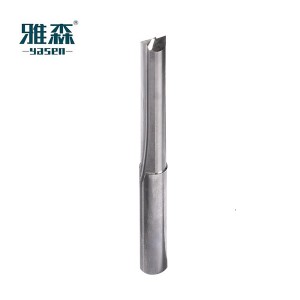

2F/3F/4F Solid carbide spiral milling cutter

For the entire processing industry, there are many different milling cutters' helix angles for different fields of application. In the field of woodworking, after a variety of tests, we finally chose the current degree range (20-25°). Too large angle will make the linear speed of the tool too fast in the machining process, resulting in too high temperature. A certain angle can indeed improve the processing efficiency and ensure that the temperature will not affect the normal processing.

For the selection of the number of edges, milling cutters used for metal processing are generally four flutes or even five flutes. However, for woodworking, because of the large temperature limit, we generally choose 1-3 flutes. While the diameter if cutter is in the range of 3-6mm, we suggest you to choose 1flutes milling cutter. For 8-10 mm, we suggest you to choose 2 flutes. For out of 10mm, 3-flute milling cutter will be your best choice. If you really have other demands or suggestions on flutes, you can tell us your ideas and we will try our best to meet your needs.

If you need a high surface finish on one hand and good processing efficiency, end mills will be a good choice for you.

Mianyang Yasen hardward Tools Co.,Ltd specialized in various of woodworking dowel drills, Hinge boring bits, quick joints and Solid carbide milling cutters,having excellent design, advanced production equipment, advanced detection equipment and professional team. Using a full set of advanced C N C machine production lines and advanced production technology. The material of tool bit will use the ultrafine particles of tungsten carbide, making the bit have high precision, excellent properties sharp and wearable. Controlling the product strictly and do not allow any defective products into the market. All of them are the Yasen‘s prominent characteristics. Whatever the management layer, the executive layer or the service staff all can assist the customers to solve all of the problems with the classic professionally quality and enthusiastic service.

The sophisticated equipment and the lasted technology produce good quality of product. The high quality micro grain carbide mills, forming tools, drills and reamers from Yasen have established a high reputation in Chinese Mainland, Southeast Asia, Eastern Europe and South American market.

The company follows the professional standard of operation philosophy—Profession, Innovation, Service class, and the management aim—Quality first, Customer superior. Providing the most durable professionally high-quality cutter for the development of wood industry.