-

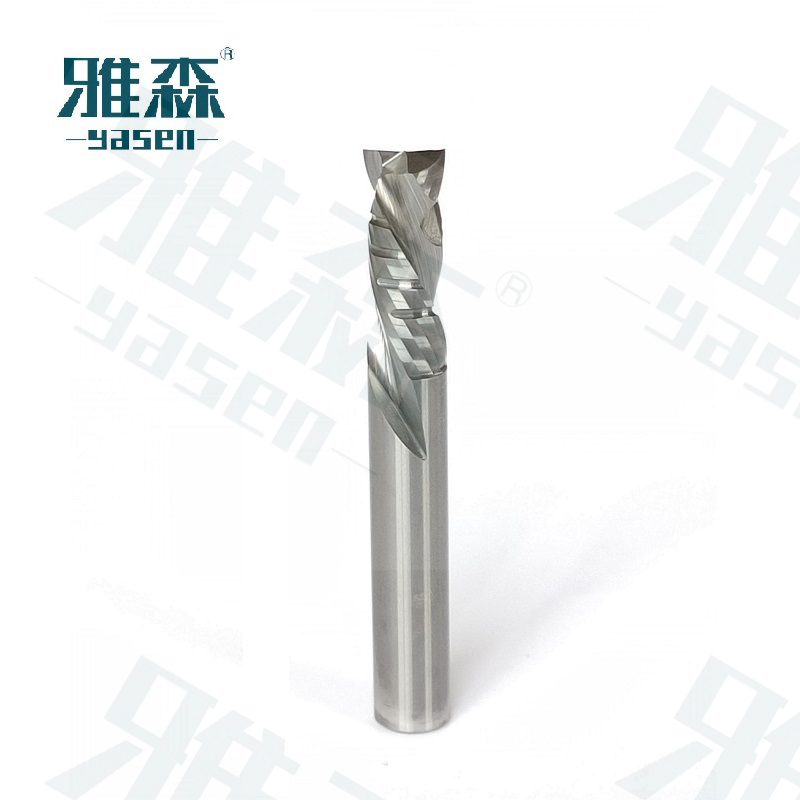

solid carbide bit CNC Machining Drill Bits for Aluminum YASEN Factory Direct Sale High Quality

Technical Details:

- Premium quality super-Tungsten Carbide

- 2 spiral cutting edges(Z2)

- Provide excellent finish on bottom side of the workpiece

- Upward chip ejection

-

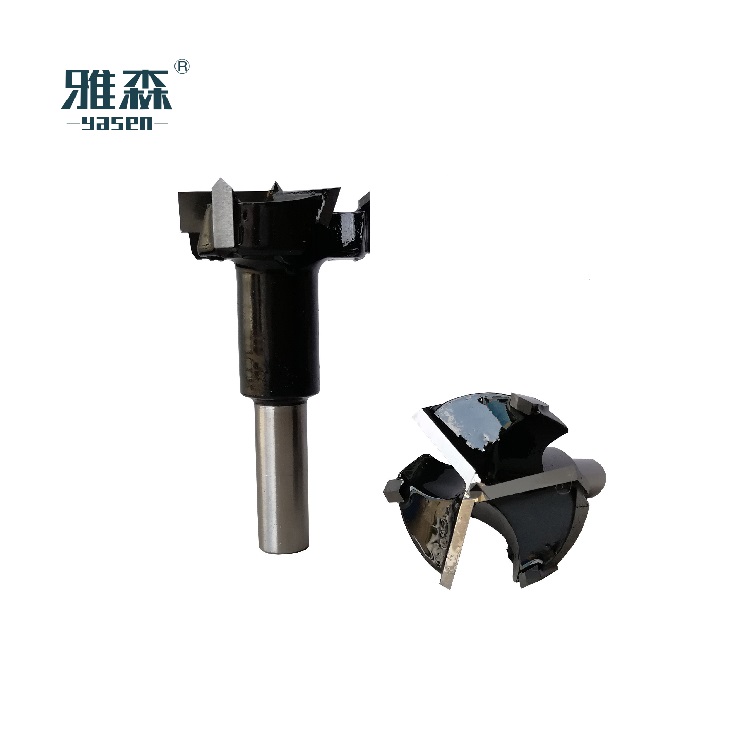

15MM Diameter CNC Machining Hinge Boring Drill Bits for Wood YASEN Factory Direct Sale

Technical Details :

- Super -strength carbide

- Cutter portionn coated with orange or black

- TCT head with precision balanced center point

- 2 percision ground cutting edge (4z)

Application : Ideal for hinges .

Used on boring machine equipped with chunk or adaptors

-

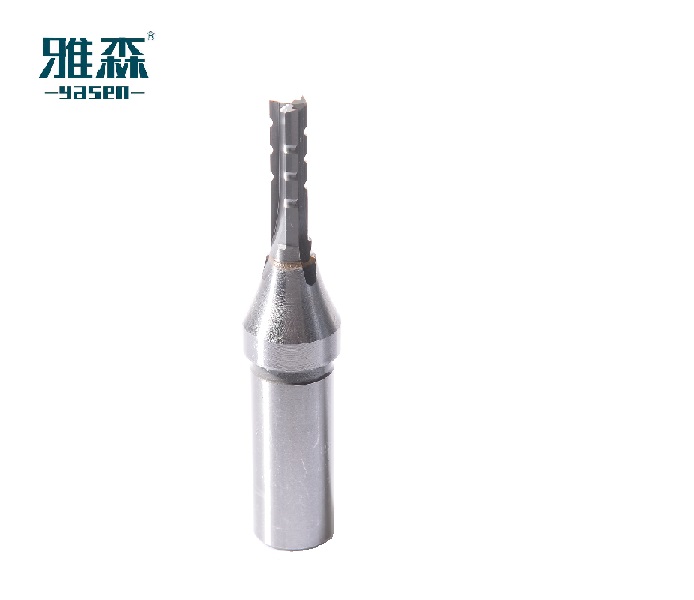

tungsten carbide step drill bit for woodworking YASEN Manufacture Carpenter Custom

CNC processing process to ensure the production of high precision and quality products

Because CNC machining equipment can operate autonomously without any manual operation, they can avoid the possibility of product defects caused by human error. Through advanced management processes and software programs, CNC machining equipment provides higher accuracy without any defects.

-

35mm Boring Bits drilling bits cnc for wood Yasen

Technical Details:

Super- strength steel

Cutter portion coated with orange or black

TCT head with precision balanced center point .

3 precision ground cutting edges(z3).

Parallel shank with driving flat and adjustable screw .

Aplication:

Ideal for hinges

Used on boring machines equipped with chunks or adaptors .

Used for drilling accurate and clean-cut blind holes in MDF , plywood ,laminated , hard and soft wood

-

3 flutes spiral Boring Bits drilling dowel drill bits set for Woodworking YASEN Manufacturer

Technical Details:

- Premium quality super -strength steel + tungsten carbide

- STC spiral portion with center point -3 cutting edges (z3)-2 spiral flutes

- 2 curved ,negatively ground spurs (v2)-parallel shank with drilling flat and adjustable screw length

Application:

Used on boring machines or with chunks for drilling blind holes in solid wood ,wood composites ,plywood ,hard and soft wood and laminated materials

-

Compression Router Bit Tools Cutters Plywood Board for woodworking YASEN End Mills

Technical Details:

- Premium quality super-Tungsten Carbide-2+2 spiral cutting edges(z2+2)

- Provides excellent finish on both top and bottom side of the workpiece.

- The upcut provides an excellent finish on the bottom edge.

- The downcut provides an excellent finish on the top edge .

Application:

For an excellent edge finish on the bottom side of laminates and double sided melamines,Can also be used with hardwoods and other wood composites.

For fast feed rates on CNC routers,machining centers and point to point machines for ripping,panel sizing,template routering and other routing applications.

-

CNC Milling Cutter Cutting Tool ball nose End Mill Router Bit Carbide Wood tools YASEN Manufacturer

Technical Details:

- Premium quality super-Tungsten Carbide

- 2 spiral cutting edges(Z2)

- Tooth depth max 0.3mm

- For fast routing on CNC equpiment when edge finish is less important

- Upward chip ejection

Application:

For fast removal of material in panel sizing operations.

For fase feed rates on CNC routers , machining centers and point to point machianes for ripping ,panel sizing ,template routing and other routing applications

-

End Mills Compression Router Bit with teeth -up and down cut Tools Cutters woodworking Router YASEN Wood Cutting

Technical Details:

- Premium quality super-Tungsten Carbide-2+2 spiral cutting edges(z2+2)

- Provides excellent finish on both top and bottom side of the workpiece.

- The upcut provides an excellent finish on the bottom edge.

- The downcut provides an excellent finish on the top edge .

Application:

For an excellent edge finish on the bottom side of laminates and double sided melamines,Can also be used with hardwoods and other wood composites.

For fast feed rates on CNC routers,machining centers and point to point machines for ripping,panel sizing,template routering and other routing applications.

-

TCT 3 flutes compression bits tungsten carbide YASEN new arrivals manufacture wholesale tungsten carbide

Technical Details:

- 3 spiral cutting edges(Z3)

- Provide excellent finish on bottom side of the workpiece

- Upward chip ejection

Application:

Used on boring machines alone and dowel drilling devices .

Use for drilling through holes in solid wood ,wood composites ,MDF , plywood ,hard and soft wood.

-

2 flutes solid Carbide ball Nose end mill for woodworking YASEN high quality

Technical Details:

- Premium quality super-Tungsten Carbide

- 2 spiral cutting edges(Z2)

- Provide excellent finish on bottom side of the workpiece

- Upward chip ejection

Application:

For an excellent edge finish on the bottom side of laminates and melamines,Can also be used with hardwoods and other wood composites.

For fast feed rates on CNC routers,machining centers and point to point machines for ripping,panel sizing,template routering and other routing applications.

-

3 flutes solid Carbide hinge boring drill Bits for woodworking YASEN high quality

Technical Details:

Super- strength steel

Cutter portion coated with orange or black

TCT head with precision balanced center point .

3 precision ground cuttiong edges(z3).

Parallel shank with driving flat and adjustable screw .

Application:

Ideal for hinges

Used on boring machines equipped with chunks or adaptors .

Used for drilling accurate and clean-cut blind holes in MDF , plywood ,laminated , hard and soft wood

-

TCT 3 Flutes Sotting Bits with Teeth CNC Router Machine Woodworking YASEN Factory Direct Sales Tungsten Drill Carbide

Technical Details:

- Premium quality super-Tungsten Carbide+Strength Steel

- 3 straight cutting edges(Z3)

- Provide excellent finish on bottom side of the workpiece

- Upward chip ejection

Application:

Used on boring machines alone and dowel drilling devices .

Use for drilling through holes in solid wood ,wood composites ,MDF , plywood ,hard and soft wood.