Products

Professional China Cnc Drill Bits - TCT CNC straight flute wood cutters router bits – Yasen

Professional China Cnc Drill Bits - TCT CNC straight flute wood cutters router bits – Yasen Detail:

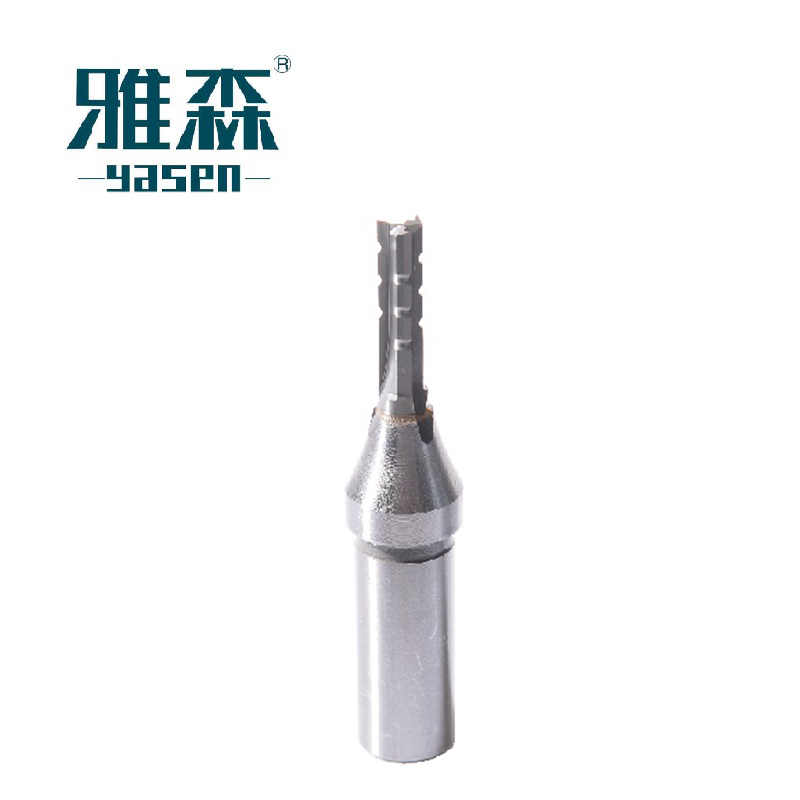

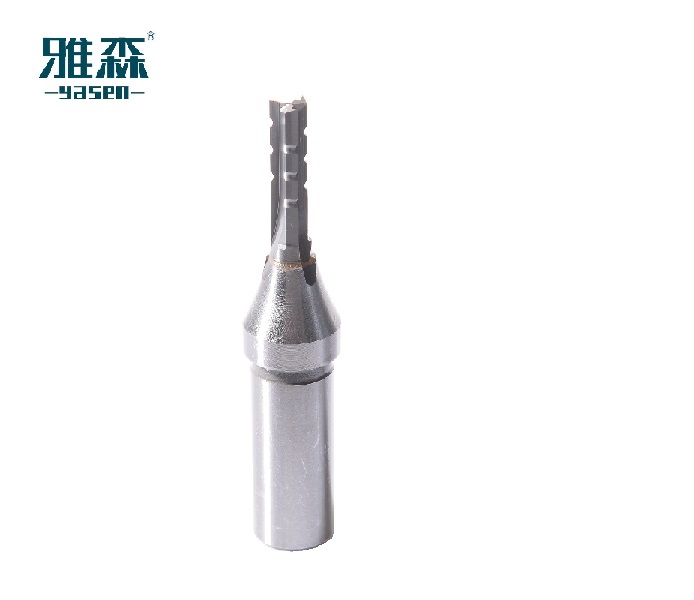

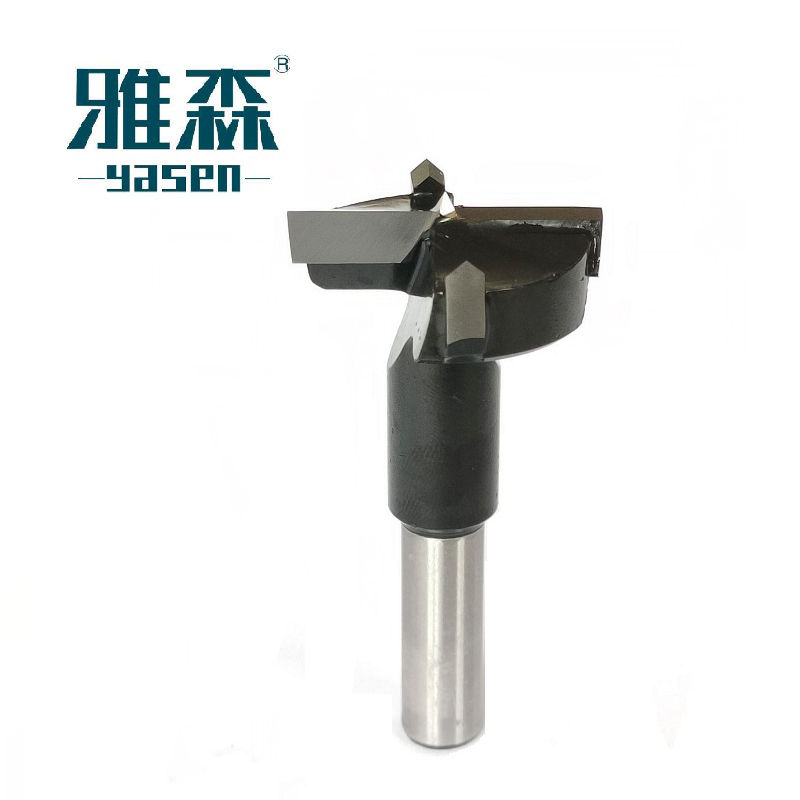

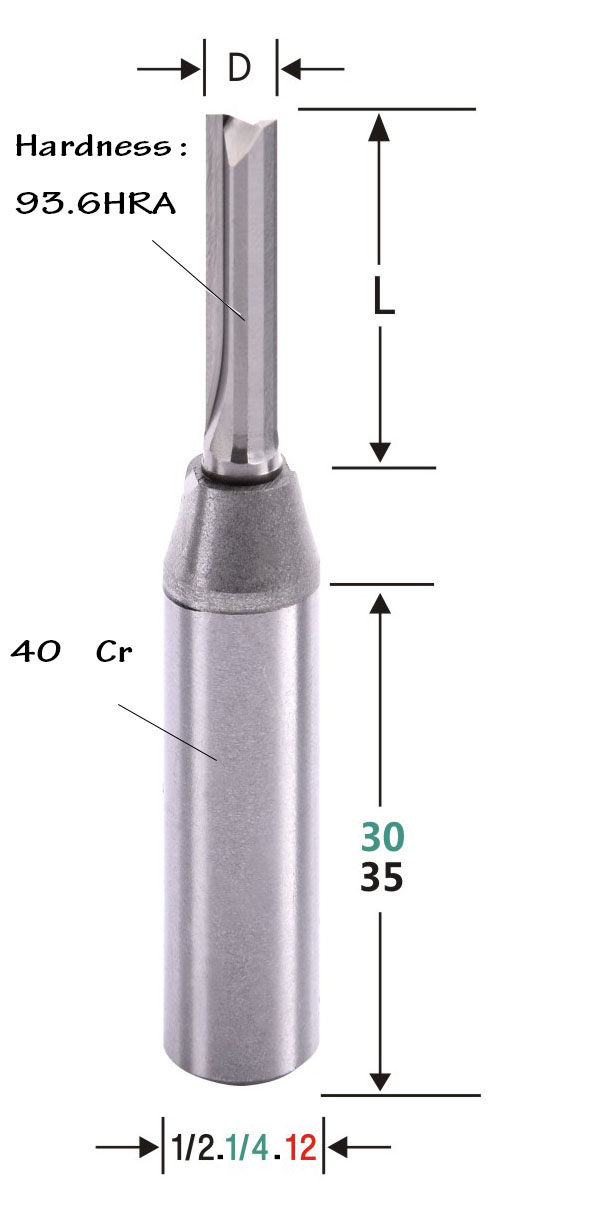

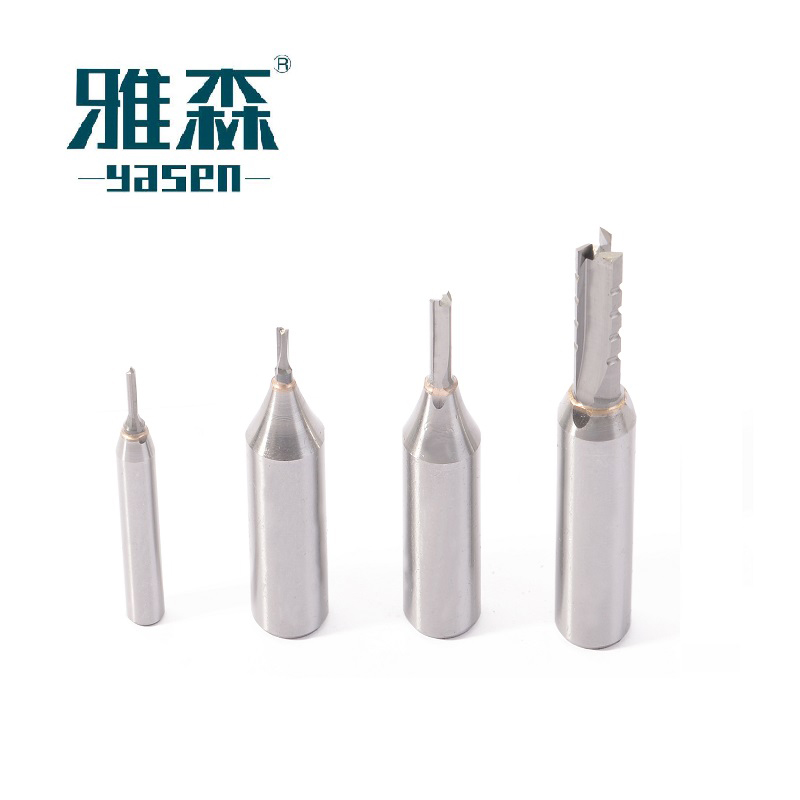

For the shank design of TCT router bits, there are many kinds of shank – straight shank, big head shank, positioning ring shank and other design. Except straight shank, these designs are for positioning when the user uses it, to ensure the same position for each clamping, reduce tool setting and facilitate use.

At the same time, we can also make adjustments to the handle according to the customer’s requirements for the finish of the handle. These are accomplished by changing materials as well as processes.

We have also added teeth design to the three-flute router bits. These teeth increase the volume of cutter and cutting capacity of the milling cutter. And at the same time, they are quieter when used, reducing noise pollution.

For each batch of TCT router bits, we have our own sampling test and then mass production to ensure the quality of each bits.

In the production process, whether welding or grinding, we use fully automatic production methods to produce router bits. The automated production structure also greatly improves our production efficiency and precision.

Because Straight flute would not make edge explosion, and has better chip removal.

There are customers all over the world, so that the technology of TCT is quite mature. We can basically meet the different requirements of various regions.

If you need a high surface finish on two hand and cheaper price, TCT router bits will be a good choice for you.

| Number | Handle diameter | Number of teeth | Blade diameter/D | Blade length/L |

| 160101/160201/160301 | 1/2,1/4,12 | 1 | 1 | 4 |

| 160102/160202/160302 | 1/2,1/4,12 | 1 | 1.5 | 5 |

| 160103/160203/160303 | 1/2,1/4,12 | 2 | 2 | 6 |

| 160104/160204/160304 | 1/2,1/4,12 | 2 | 3 | 10/12/15 |

| 160105/16020/160305 | 1/2,1/4,12 | 2 | 3.5 | 12/15 |

| 160106/160206/160306 | 1/2,1/4,12 | 2 | 4 | 10/12/15 |

| 160107/160207/160307 | 1/2,1/4,12 | 2 | 4 | 20/27 |

| 160108/160208/160308 | 1/2,1/4,12 | 2 | 4.5 | 15 |

| 160109/160209/160309 | 1/2,1/4,12 | 2 | 5 | 12 |

| 160110/160210/160310 | 1/2,1/4,12 | 2 | 5 | 15 |

| 160111/160211/160311 | 1/2,1/4,12 | 2 | 5 | 20 |

| 160112/160312 | 1/2,12 | 2 | 5.5 | 12 |

| 160113/160313 | 1/2,12 | 2 | 5.5 | 15 |

| 160114/160314 | 1/2,12 | 2 | 6 | 12 |

| 160115/160315 | 1/2,12 | 2 | 6 | 15 |

| 160116/160316 | 1/2,12 | 2 | 6 | 20 |

| 160117/160317 | 1/2,12 | 2 | 6 | 25 |

| 160118/160318 | 1/2,12 | 2 | 7 | 25 |

| 160119/160319 | 1/2,12 | 2 | 8 | 25/30 |

| 160120/160320 | 1/2,12 | 2 | 10 | 30 |

1. Fine partides of tungsten steel with the technology of ow temperature welding prooess.

2. The four axos CNC gnnding machine has the technology of one-step molding make higher precision

Product detail pictures:

Related Product Guide:

High-quality comes 1st; support is foremost; business is cooperation" is our small business philosophy which is regularly observed and pursued by our organization for Professional China Cnc Drill Bits - TCT CNC straight flute wood cutters router bits – Yasen , The product will supply to all over the world, such as: luzern, Salt Lake City, Mexico, So We also continuously function. we, focuse on high quality, and are conscious of the importance of environmental protection, most of the merchandise are pollution-free, environmentally friendly products, reuse on the solution. We've Updated our catalog, which introduces our organization. n detail and covers the primary items we provide at present, You may also visit our web-site, which involves our most recent product line. We look forward to reactivating our company connection.

Mianyang Yasen hardward Tools Co.,Ltd specialized in various of woodworking dowel drills, Hinge boring bits, quick joints and Solid carbide milling cutters,having excellent design, advanced production equipment, advanced detection equipment and professional team. Using a full set of advanced C N C machine production lines and advanced production technology. The material of tool bit will use the ultrafine particles of tungsten carbide, making the bit have high precision, excellent properties sharp and wearable. Controlling the product strictly and do not allow any defective products into the market. All of them are the Yasen‘s prominent characteristics. Whatever the management layer, the executive layer or the service staff all can assist the customers to solve all of the problems with the classic professionally quality and enthusiastic service.

The sophisticated equipment and the lasted technology produce good quality of product. The high quality micro grain carbide mills, forming tools, drills and reamers from Yasen have established a high reputation in Chinese Mainland, Southeast Asia, Eastern Europe and South American market.

The company follows the professional standard of operation philosophy—Profession, Innovation, Service class, and the management aim—Quality first, Customer superior. Providing the most durable professionally high-quality cutter for the development of wood industry.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.